Biomass gasification process can be achieved in many apparatuses, such as upward and downward fixed bed gasifier and entrained-flow bed gasifier. Due to the superior mixing rate of heterogeneous phases, exceptional heat and mass transfer and uniform temperature distribution, fluidized bed reactors have been commonly applied to conduct the process of biomass gasification. To describe such process, especially particle and gas motions in the dense gas–solid reactive flow in fluidized beds, computational fluid dynamics (CFD) is usually proposed as a useful tool.

Recently, Dr Kun Luo from State Key Laboratory of Clean Energy Utilization, Zhejiang University Shanghai Institute for Advanced Study, Zhejiang University, and his collaborators employed MP-PIC method to model the biomass steam-gasification process in an industrial-scale DFBG with 8MWth input in the open-source platform OpenFOAM with the aim to explore the particle behaviors (e.g., particle velocity, slip velocity and heat transfer coefficient), and to investigate the relationships between them.

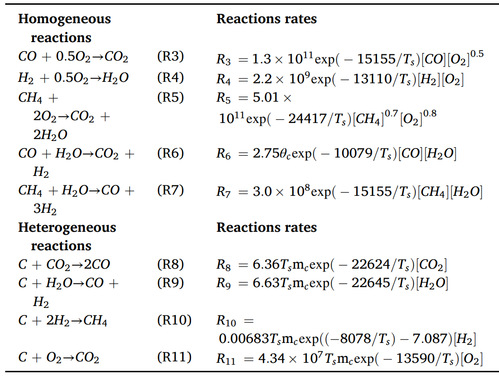

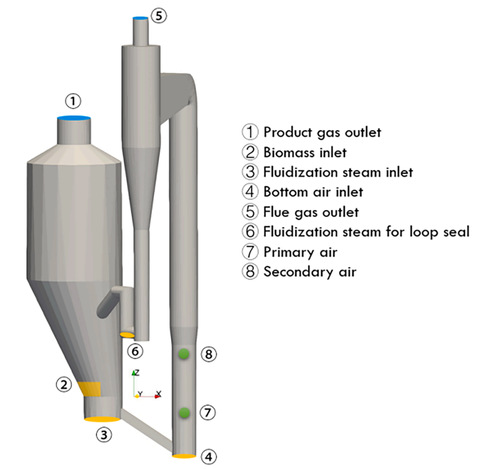

The governing equations for gas, solid and gas–solid coupling as well as Main homogeneous and heterogeneous reactions as well as schematic representation of the DFBG geometry and boundary conditions in this work are as below:

The model validation is successfully conducted by the gas molar fraction, pressure drops and solid circulation rate. Main conclusions can be epitomized as:

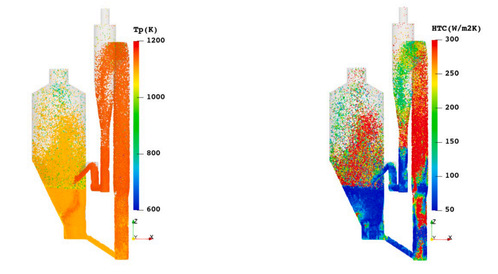

(1) Due to the different fluidization regimes existing in the gasifier and combustor, particle velocity along the vertical direction presents distinct values. More chaotic motions of particles occur in the combustor, and sand behaves violent motions in the gasifier freeboard due to the intense homogeneous and heterogeneous reactions.

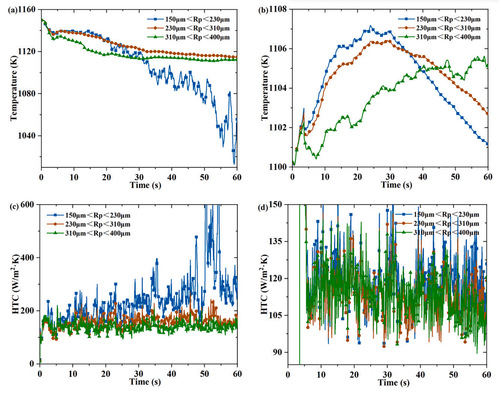

(2) Combustor sand has larger temperature than that in the gasifier due to the strong exothermic combustion reactions. The mean values of heat transfer coefficient (HTC) of the combustor sand, gasifier sand and biomass particles are about 154.6 W/(m2⋅K), 114.7 W/(m2⋅K) and 76.4 W/(m2⋅K), respectively. Increasing the inventory height makes the peaks of particle temperature and HTC move rightwards in the coordinate.

(3) In general, particle dispersion coefficients fluctuate around a fixed value, and biomass particles have largest dispersion coefficients among all types of particles in the reactor. For all the particles, dispersion coefficients along axial directions are much higher than those along radial directions, which mainly caused by the fluidization agent.

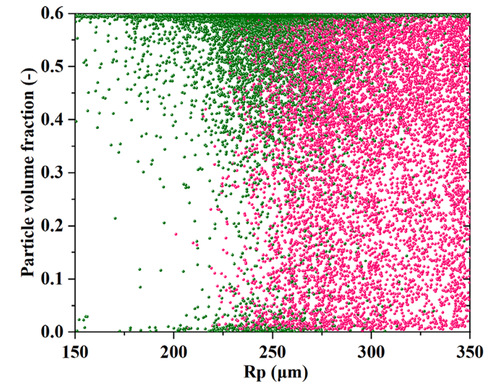

(4) Small particles are easily entrained by the fluidization agent to the upper region and thus have larger vertical velocity and dispersion coefficients. In the gasifier, large particles tend to have large slip velocity due to their dominant inertia. Because of the fast fluidization regime existing in the combustor, particles in the combustor have lower average volume fraction than that in the gasifier.

The work was published in Chemical Engineering Journal, and could be accessed at https://www.sciencedirect.com/science/article/pii/S1385894723000438.

About Professor Luo

Kun Luo is a professor at Zhejiang University. He is a Distinguished Young Scholar, and is a member of the Chinese Society of Engineering Thermophysics, Deputy Secretary General of the Multiphase Flow Committee of the Chinese Society of Engineering Thermophysics, and Deputy Secretary General of the Process Simulation and Simulation Committee of the Chinese Chemical Society.

He received his bachelor's degree from Wuhan University of Water Resources and Electric Power in July 2000 and was promoted to professor in December 2010 after receiving his Ph.D. in engineering thermophysics from Zhejiang University in March 2005. University (2003).

For many years, he has been engaged in theoretical modeling and numerical simulation of complex multi-scale coupled problems in power and environmental engineering, including computational multiphase flow, computational combustion, multi-scale simulation of wind energy utilization, and multi-scale modeling of air quality in atmospheric pollution areas. He proposed a new method for direct numerical simulation of complex large-scale multiphase turbulent combustion processes, discovered new phenomena and mechanisms of coupling multiphase turbulent combustion processes at the interface, developed a new model for more accurate engineering calculations, and successfully applied it to engineering practice, which brought obvious economic and environmental benefits. As a project leader and research manager, he has conducted more than ten national/provincial research projects and published more than 200 papers in scholarly journals.

About SIAS

Shanghai Institute for Advanced Study of Zhejiang University (SIAS) is a jointly launched new institution of research and development by Shanghai Municipal Government and Zhejiang University in June, 2020. The platform represents an intersection of technology and economic development, serving as a market leading trail blazer to cultivate a novel community for innovation amongst enterprises.

SIAS is seeking top talents working on the frontiers of computational sciences who can envision and actualize a research program that will bring out new solutions to areas include, but not limited to, Artificial Intelligence, Computational Biology, Computational Engineering and Fintech.