Many engineering applications request soft materials to maintain tough under monotonic loads, and fatigue-resistant under cyclic loads. While fracture toughness of a soft material can be enhanced by orders of magnitude, its fatigue threshold remains insusceptible. To overcome this, professor Shaoxing Qu and his colleagues from Zhejiang University, China and The City College of New York, US applied a crack softening(CTS) concept and their work “Tough and fatigue-resistant polymer networks by crack tip softening” was published in Proceedings of the National Academy of Sciences recently.

Soft materials fail by crack propagation under external loads. While fracture toughness of a soft material can be enhanced by orders of magnitude, its fatigue threshold remains insusceptible. Professor Qu and colleagues proposed a CTS concept to simultaneously improve the toughness and threshold of a single polymeric network. They have selected polyacrylamide hydrogels as a model material, and cured polymer network by a normal crosslinker and a light-degradable crosslinker.

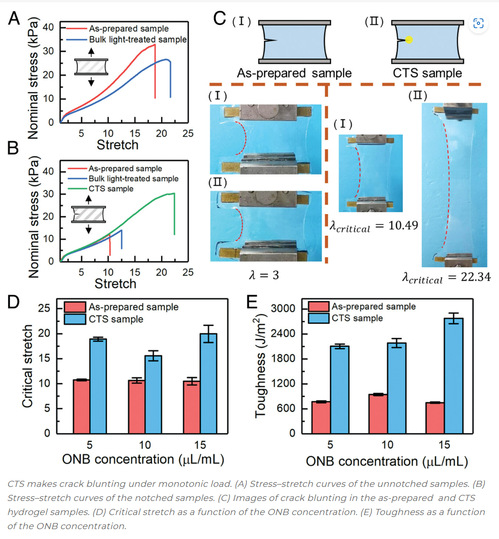

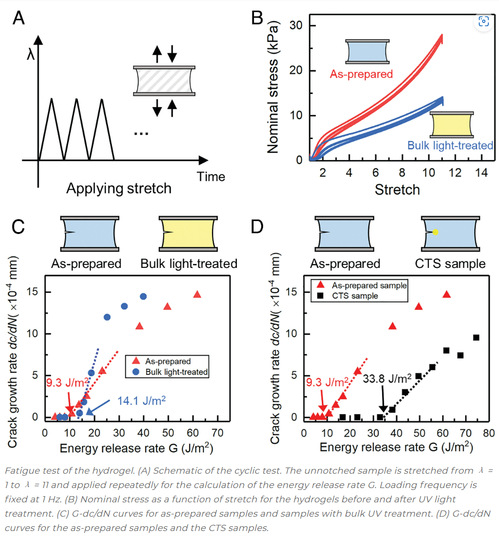

The authors applied monotonic loads and cyclic loads to polyacrylamide hydrogels and characterized the mechanical properties of pristine samples and CTS samples. A light-treated hydrogel is softer and more elastic than an un-treated one. The pristine sample has a fracture toughness of 748.3 ± 15.19 J/m2 and a fatigue threshold of 9.3 J/m2. By comparison, the CTS sample has a fracture toughness of 2,774.6 ± 127.14 J/m2 and a fatigue threshold of 33.8 J/m2. Experimental results show that fracture toughness and fatigue threshold have been enhanced by about four times.

The authors concluded that the stress de-concentration and elastic shielding at the crack tip contributed to the enhancement. Different from the “fiber/matrix composite” concept and the “crystallization at the crack tip” concept, the CTS concept here is generic to many materials systems and applicable to different geometrical singularity regions, and to various external loads (monotonic or cyclic). The crack retardation method described in this publication provided another option to simultaneously enhance the toughness and threshold, which improves the reliability of soft devices during applications.

To access the article, please visit http://www-pnas-org-s.webvpn.zju.edu.cn:8001/doi/10.1073/pnas.2217781120.

About Professor Qu

Dr. Shaoxing Qu is a Changjiang Chair Professor (from Ministry of Education, China) and Distinguished Young Scholar grant from National Natural Science Foundation of China. He serves as the Director of the Key Laboratory of Soft Machines and Smart Devices of Zhejiang Province.

He got his bachelor degree from University of Science and Technology of China in1997, Master of Engineering from Tsinghua University in 2000, and Ph.D. from UIUC in 2004. After spending two years at Brown University as postdoc, he joined Zhejiang University in 2006 and was promoted to full professor in 2011. He has published more than 180 journalpapers.

Dr. Qu’s primary research interests include soft materials and soft machines, insect-scalerobots, mechanics of composites, and micro/nano mechanics.

About SIAS

Shanghai Institute for Advanced Study of Zhejiang University (SIAS) is a jointly launched new institution of research and development by Shanghai Municipal Government and Zhejiang University in June, 2020. The platform represents an intersection of technology and economic development, serving as a market leading trail blazer to cultivate a novel community for innovation amongst enterprises.

SIAS is seeking top talents working on the frontiers of computational sciences who can envision and actualize a research program that will bring out new solutions to areas include, but not limited to, Artificial Intelligence, Computational Biology, Computational Engineering and Fintech.