Hydrogel adhesion regulation remains a key challenge in applications of stretchable electronics, tissue engineering, and soft robotics. Whereas existing strategies are focused on enhancing adhesion, the underlying mechanics of on-demand mechanical regulation from adhesion promotion to adhesion reduction receives insufficient attention.

Recently, Professor Qu Shaoxing from Zhejiang University proposed an effective method to expand the energy dissipation process zone ahead of the crack front by invoking a periodic pattern for elastic heterogeneity, which also exhibits directional dependence in adhesion toughness. They employed a digital light processing (DLP)-based 3D printer to fabricate hydrogel elastic heterogeneity (periodic ligaments) with controlled structural and interfacial properties.

The authors found out that different from the debonding process from a homogeneous hydrogel interface, the crack in a heterogeneous layer propagates discretely and collaboratively, and the advance of the crack requires local re-initiation of a new crack at the leading ligament. Due to the lack of constraints in the lateral direction, the ligaments can accommodate more displacement and consume significantly large energy before the re-initiation of the crack front.

Fig. 1. Schematics of homogeneous bonding and heterogeneous bonding under 90° peel. (a) For the homogeneous bonding case, a small region of the crack front deforms to resist crack propagation. (b) Top view of elastic ligament arrangement for the heterogeneous bonding case. (c) The peeling direction is perpendicular to the orientation of the elastic ligament. (d) The peeling direction is parallel to the orientation of the elastic ligament.

Without modifying surface chemistry, experiments shew that the adhesion of heterogeneous interfaces implemented by 3D printing could enhance peak force by 6-fold or weaken interfacial toughness to 1/30, as compared to the case of a homogeneous interface.

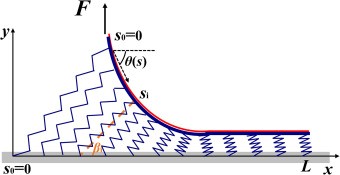

Fig. 2. Mechanical model of hydrogel with elastic ligaments peeled from a rigid substrate. Blue, red, and gray represent the hydrogel, backing layer, and glass substrate, respectively. The orange dashed line represents the tangential angle of the first elastic ligament.

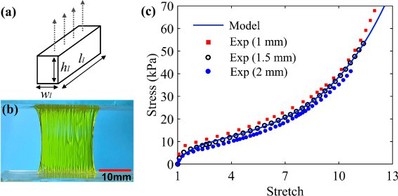

Fig. 3. (a) Schematic representation of a single elastic ligament subjected to pure shear deformation. (b) Snapshot of a single elastic ligament subjected to pure shear deformation. (c) The Second-order Ogden model fits well with the stress-displacement curve of a single elastic ligament under tension.

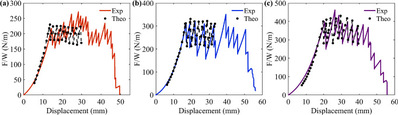

Based on a variational principle, the authors performed analytical formulations and finite element simulations to quantify the heterogeneous behaviors. The analysis captured the instability phenomenon and predicts the maximum peel force. Combined experimental, theoretical, and finite element results demonstrated the effects of geometric parameters and peeling directions on the overall adhesion toughness. Such data elucidated an energy storage mechanism, namely that the discrete elastic ligaments free of lateral constraints could enable the interface to accommodate large stretching and store intensified strain energy. The results also indicated the necessity and significance of peeling directions.

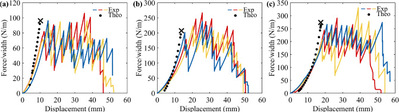

Fig. 4. Comparison between theoretical and experimental results with spacing d = 1 mm. (a)-(c) show the peeling force/width versus displacement with a ligament width of 1 mm, 1.5 mm, and 2 mm, respectively.

Fig. 5. Inclination angle (black curve) and tensile elongation of the leftmost ligament as a function of peeling force. The black circles represent the experimental data for the inclination of the first ligament.

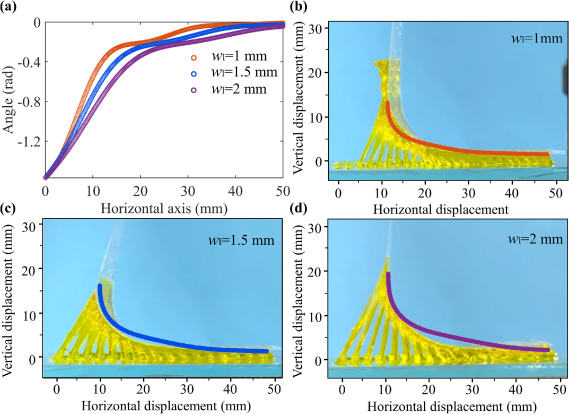

Fig. 6. (a) Inclination angle of profile versus displacement for different ligament widths under maximum peeling force. Comparison of theoretical and experimental backing layer profiles under maximum peeling force: (b) wl =1 mm; (c) wl =1.5 mm; (d) wl =2 mm.

Fig. 7. Peeling force/width versus displacement by FE analysis. (a) Numerical results for homogeneous adhesion and heterogeneous adhesion. (b-c) Snapshots of homogeneous adhesion and heterogeneous adhesion (wl =1 mm) under maximum peeling force, respectively. (d) Numerical results for the simulated enhancement ratio of the peak peeling force versus the width of hydrogel ligament (Γ0=30 J/m2).

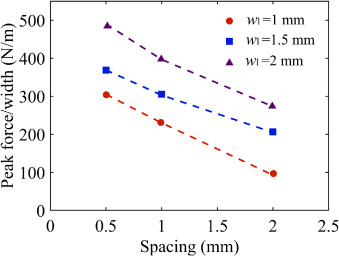

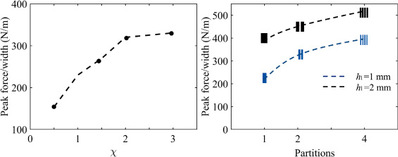

Besides, the effects of the geometry of ligament, spacing, and partition on adhesion were quantified as below:

Fig. 8. Comparison of theoretical and experimental results with spacing d = 2 mm. (a)-(c) show the peeling force/sample width versus displacement with ligament width of 1 mm, 1.5 mm, and 2 mm. The black cross indicates the peak predictions by the analytical model. Curves of three different colors correspond to three tests under the same testing parameters to show the scatters of the experiments.

Fig. 9. Calculated peak peeling force as a function of spacing for three widths.

Fig. 10. (a) Calculated peak force/sample width as a function of χ at the spacing d = 1 mm. (b) Comparison of calculated peak peeling force for different partitions under same coverage fraction.

In this work, the authors have demonstrated that the hydrogel adhesion capacity can be adjusted by invoking periodic elastic heterogeneity. Experiments, theoretical analyses, and finite element simulations were conducted to investigate the effects of the geometric parameters of elastic ligaments and peeling directions on adhesion capacity. The controllable heterogeneous interface was implemented by DLP printing, and the analytical model accounted for hyper-elasticity and fracture criterion. In terms of the simulation, the model based on the cohesive zone law confirmed the effectiveness of introducing elastic heterojunctions under different levels of intrinsic toughness. The discrete elastic ligaments without lateral constraints enable the interface to accommodate large stretching and to store more energy, while a small peeling direction gives a curved crack front and severe stress concentration, resulting in a diminished energy zone. As a result, a 6-fold enhancement in maximum peeling force was achieved when peeling in a perpendicular direction, compared with that of the homogeneous adhesion. Additionally, a difference of two orders of magnitudes was demonstrated at φ = 90° and 0°. The work enlighted on a wide range of on-demand adhesion applications including non-invasive debonding of hydrogel tissue patches, and temporary bonding-debonding of hydrogel-based flexible electronics. To understand the phenomenon further, a theoretical model was needed in the future to investigate the effect of the peeling direction on the interfacial toughness. It provided a design guideline for on-demand enhancement and detachment in hydrogel interface applications.

The work was published as ‘Mechanics of regulatable hydrogel adhesion with elastic heterogeneity’ in Journal of the Mechanics and Physics of Solids, and to access the article, please visit https://www.sciencedirect.com/science/article/pii/S0022509623001084.

About Professor Qu

Dr. Shaoxing Qu is a Changjiang Chair Professor (from Ministry of Education, China) and Distinguished Young Scholar grant from National Natural Science Foundation of China. He serves as the Director of the Key Laboratory of Soft Machines and Smart Devices of Zhejiang Province.

He got his bachelor degree from University of Science and Technology of China in1997, Master of Engineering from Tsinghua University in 2000, and Ph.D. from UIUC in 2004. After spending two years at Brown University as postdoc, he joined Zhejiang University in 2006 and was promoted to full professor in 2011. He has published more than 180 journal papers.

Dr. Qu’s primary research interests include soft materials and soft machines, insect-scalerobots, mechanics of composites, and micro/nano mechanics.

About SIAS

Shanghai Institute for Advanced Study of Zhejiang University (SIAS) is a jointly launched new institution of research and development by Shanghai Municipal Government and Zhejiang University in June, 2020. The platform represents an intersection of technology and economic development, serving as a market leading trail blazer to cultivate a novel community for innovation amongst enterprises.

SIAS is seeking top talents working on the frontiers of computational sciences who can envision and actualize a research program that will bring out new solutions to areas include, but not limited to, Artificial Intelligence, Computational Biology, Computational Engineering and Fintech.